1. What is crimping?

Crimping is the process of applying pressure to the contact area of the wire and the terminal to form it and achieve a tight connection.

2. Requirements for crimping

Provides an inseparable, long-term reliable electrical and mechanical connection between crimp terminals and conductors.

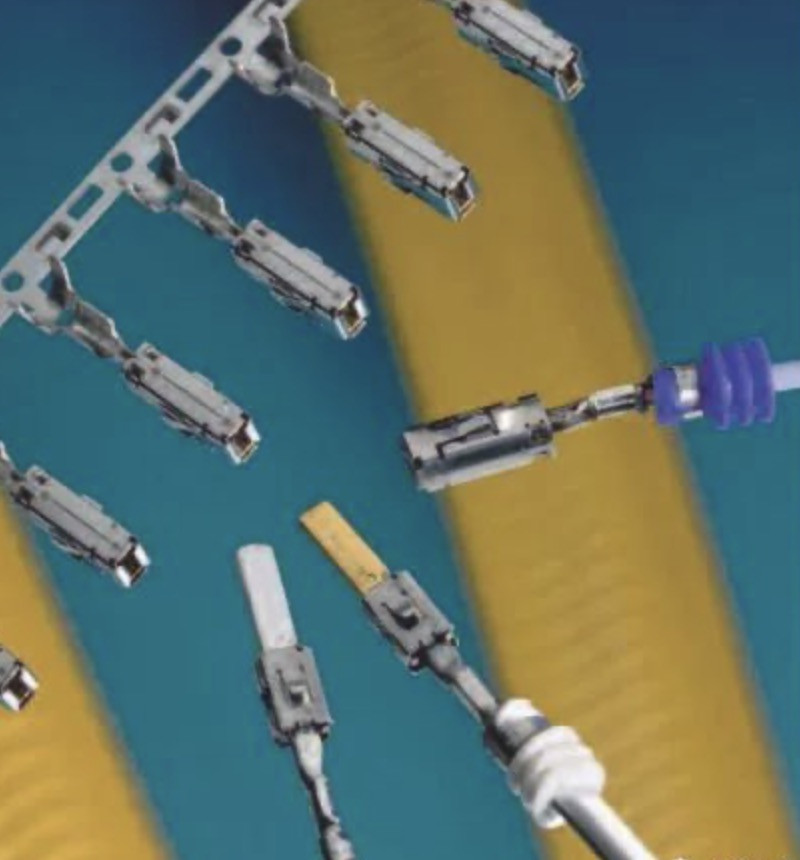

The crimping should be easy to manufacture and process.

3. Advantages of crimping:

1. The crimping structure suitable for a specific wire diameter range and material thickness can be obtained by calculation

2. It can be used for crimping with different wire diameters only by adjusting the crimping height

3. Low cost achieved through continuous stamping production

4. Crimping automation

5. Stable performance in harsh environments

4. Three elements of crimping

Wire:

1. The selected wire diameter meets the applicability requirements of the crimp terminal

2. The stripping meets the requirements (the length is suitable, the coating is not damaged, and the end is not cracked and bifurcated)

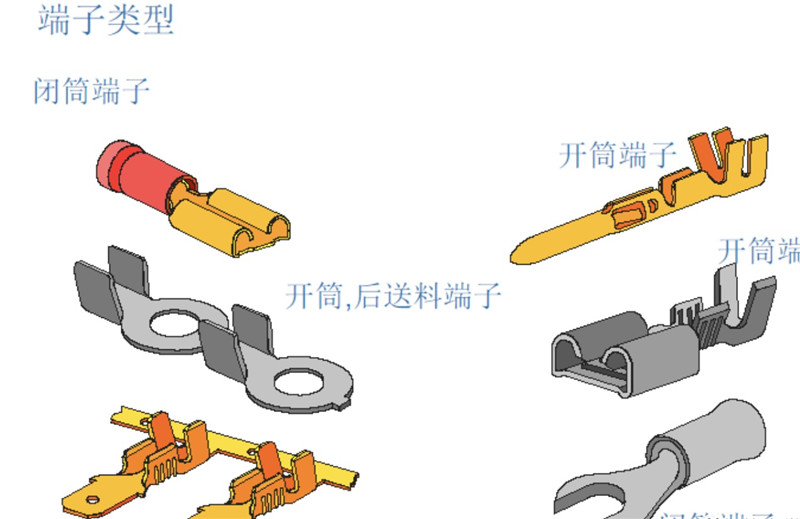

2. Terminal

Crimp Preparation: Terminal Selection

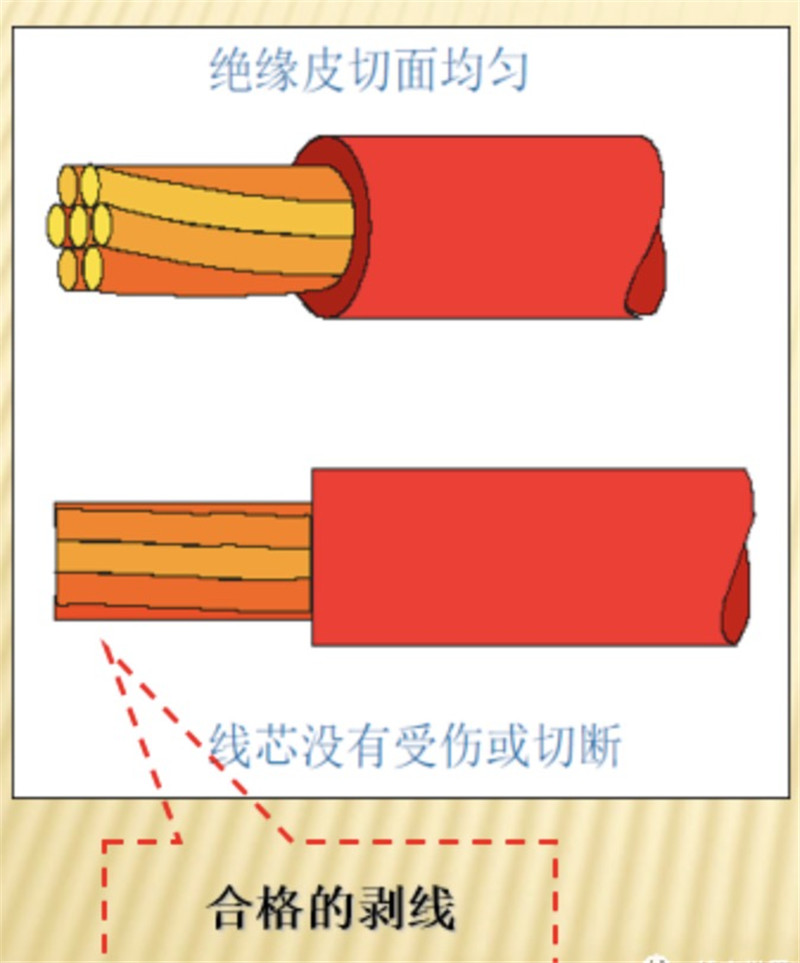

Crimp Preparation: Stripping Requirements

Wire stripping should pay attention to the following general requirements

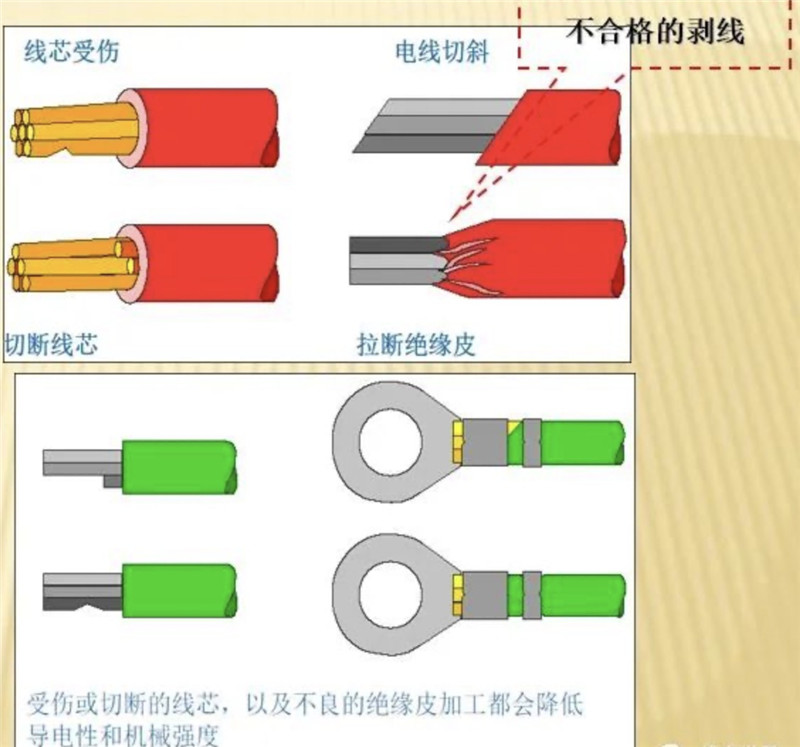

1. Conductors (0.5mm2 and below, and the number of strands is less than or equal to 7 cores), cannot be damaged or cut;

2. Conductors (0.5mm2 to 6.0mm2, and the number of strands is greater than 7 core wires), the core wires are damaged or the number of cut wires is not more than 6.25%;

3. For wires (above 6mm2), the core wire is damaged or the number of cut wires is not more than 10%;

4. The insulation of the non-stripping area is not allowed to be damaged

5. No residual insulation is allowed in the stripped area.

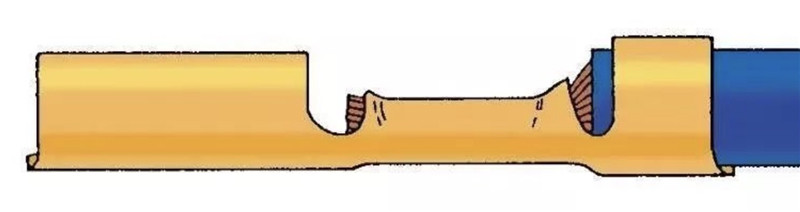

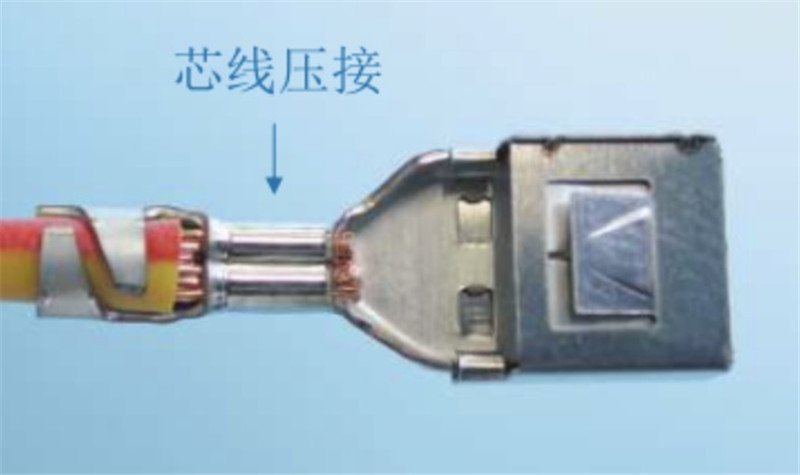

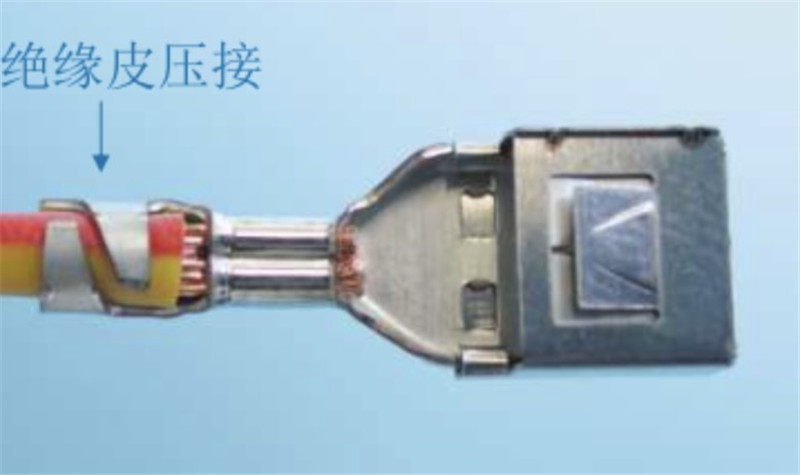

5. Core wire crimping and insulation crimping

1. There are certain differences between core wire crimping and insulation crimping:

2. Core wire crimping ensures a good connection between the terminal and the wire

3. Insulation crimping is to reduce the impact of vibration and movement on core wire crimping

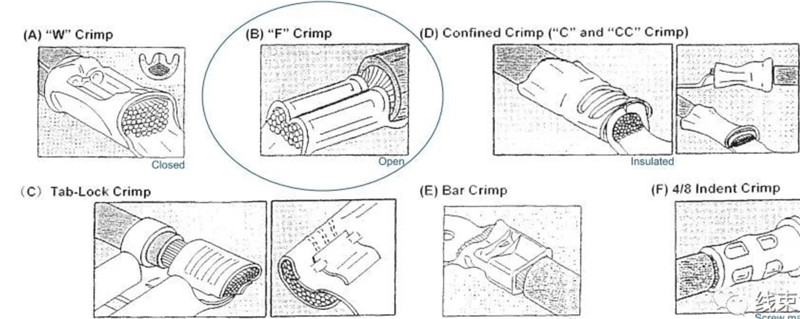

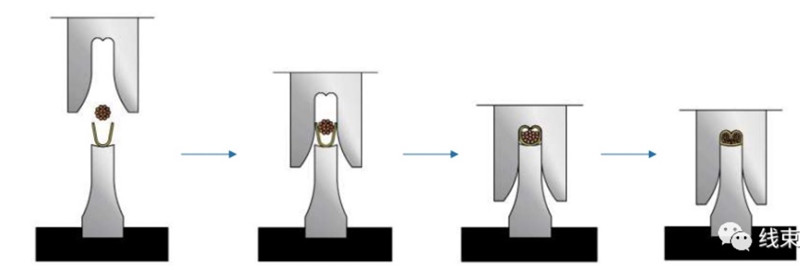

6. Crimping process

1. The crimping tool is opened, the terminal is placed on the lower knife, and the wire is fed into place by hand or mechanical equipment.

2. The upper knife moves down to press the wire into the barrel

3. The package tube is bent with the upper knife, and crimped and formed

4. The set crimping height guarantees crimping quality

Post time: Jul-04-2023