People often ask, what is the solution to tape lift? This is a common problem in wiring harness factories, but there has been no good solution.

I have arranged some methods for you to help you.

When winding a common branch

The surface of the wire harness insulator should have requirements, (such as Teflon, PTFE, low surface energy materials, etc.) the bonding effect is not good

Substrate requirements:

No dirt

No grease / oil stains

Dry

During use, the following products cannot be used:

Talcum powder

Silicone resin

Molding agent

Hand cream

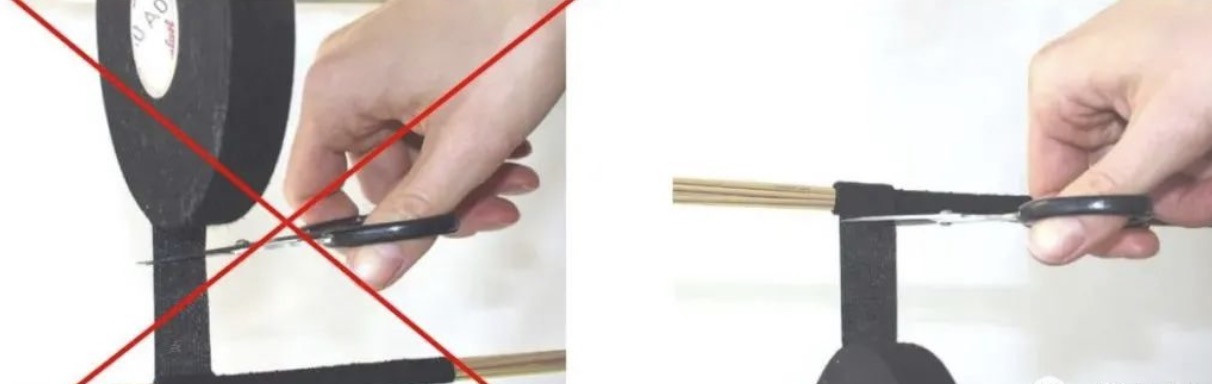

2. When the tape is pulled from the tape roll: Do not store the tape in the way shown below.

Finger (with oil) do not touch the end of the tape!

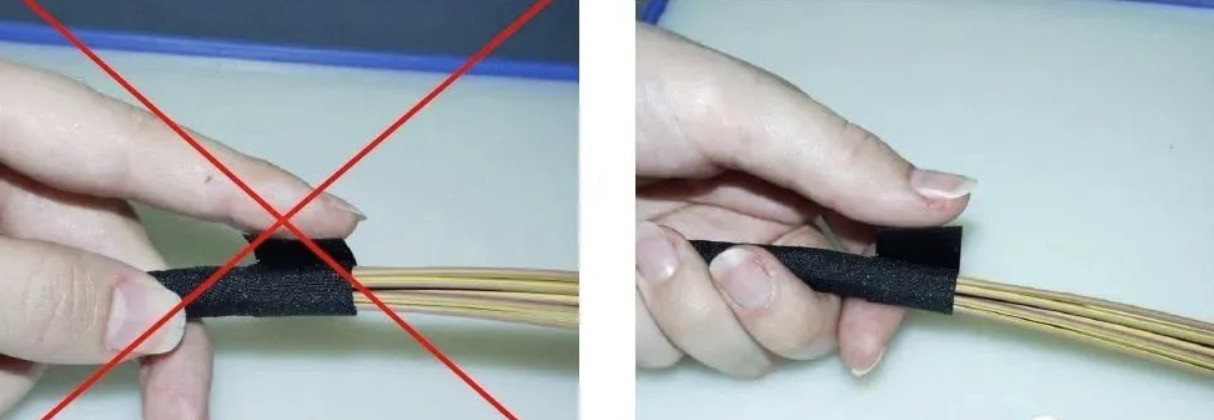

3. The spool of tape is rolled close to the wire harness, and the tape cannot be rolled too loosely (overlapping).

4. Don't stand too far away when cutting the tape.... Usually it should be cut very close to the harness.

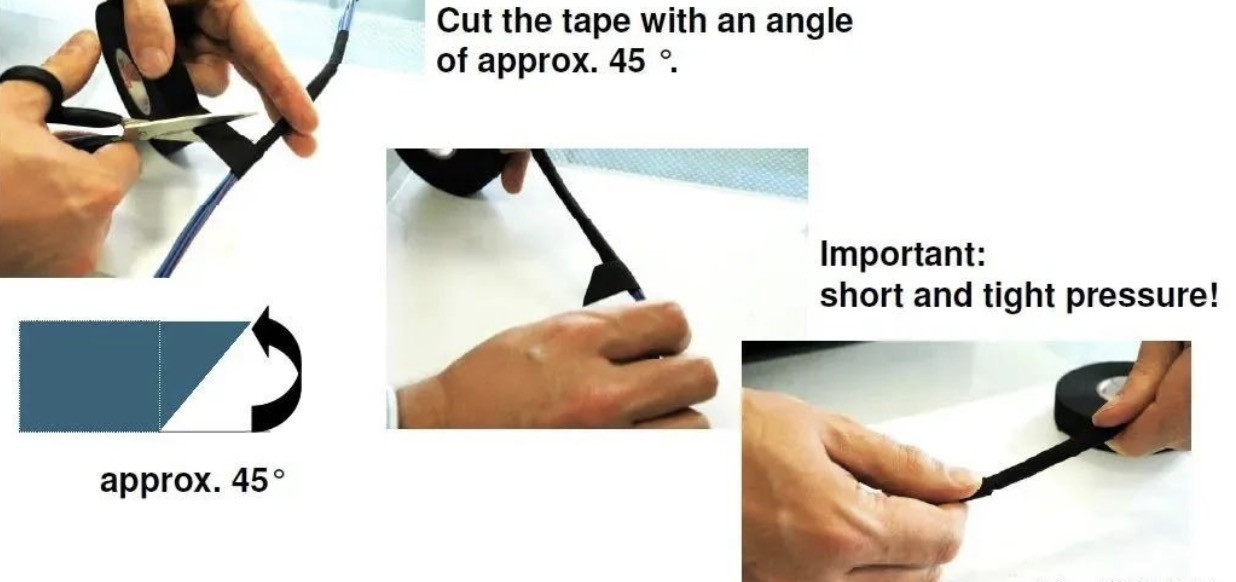

5. Diagonal cutting is more suitable for assembling. When cutting the tape, it should be at a 45-degree angle. Key points: short and tight!

6. Taping The final step must be done with short, strong thumb pressure (index finger on left, thumb on right).

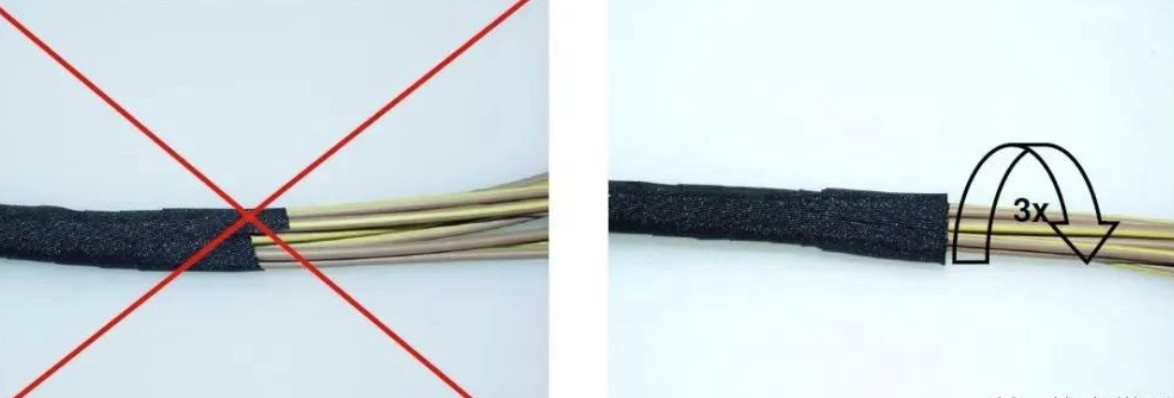

7. Never stick the end of the tape to the harness. ...to wind three times before finally ending.

8. If the edge of the tape is loosened or desilded during use, please cut it off with scissors and continue to wrap the tape.

9, when the end of the winding is relatively thick tape, need to match a PVC tape or PE tape.

10. The viscosity of the wire harness tape decreases – for example, the viscosity of the wire harness tape will decrease due to the influence of the temperature in winter. At this time, the tape should be stored in an incubator.

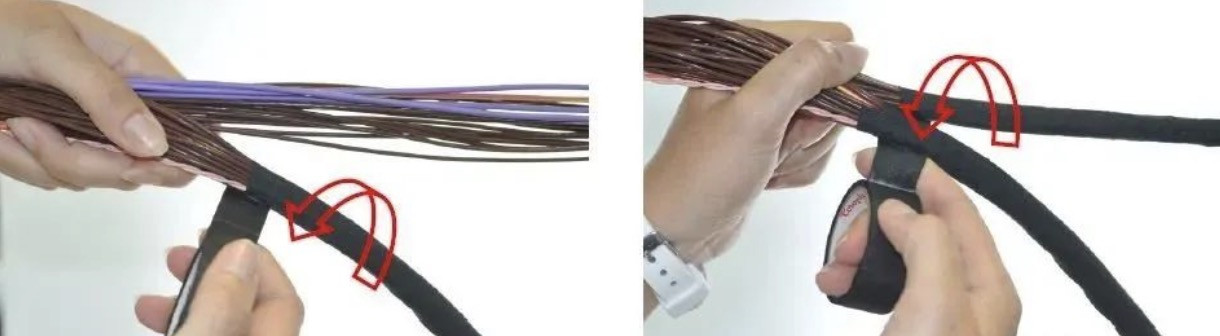

How to prepare a harness with branches?

1. Start winding from the branch line and gradually progress to the main line;

2. Wrap in the direction from the upper branch to the lower branch;

3. Place the two branch lines at the desired angle;

4. Wrap the tape again around the already taped lower branch plus the upper branch;

5. Then only wind the lower branch again;

6. Then wrap the two branches twice, and then wrap the main trunk bundle, in case the diameter is relatively large;

7. Wrap up the top branch again;

8. Start wrapping the main trunk bundle.

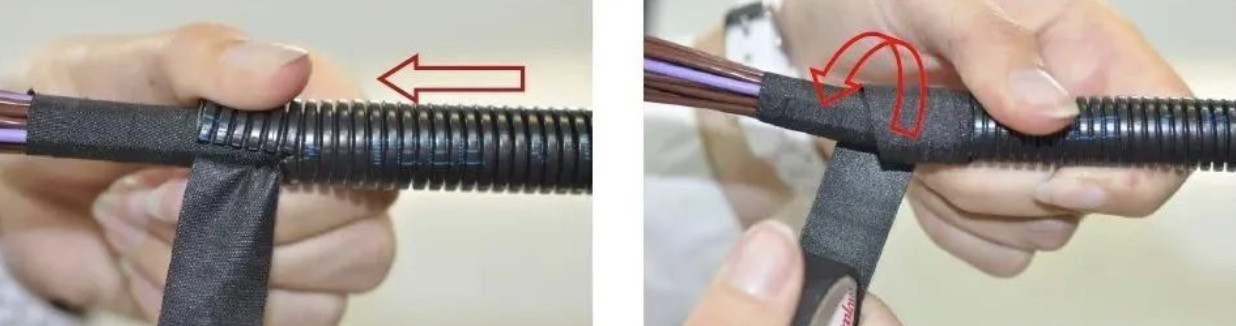

How to install bellows?

1. Wrap a small piece of wire harness and face the direction of the pipe entrance;

2. If it is too close to the pipe, you can use a tool to open a small slit;

3. Move the pipe over the bonded section and put the tape into the seam;

4. Wrap a layer of tape on the pipe;

5. Then continue with rolling the wiring harness.

Summarize

In fact, the tape lifting has nothing to do with the unwinding force of the wire harness tape itself. It can only be said that the unwinding force of the wire harness tape can be seen from a certain aspect, which is a continuous control of the production quality of this tape.

The appearance of tape products can be distinguished by looking at his product process. The cut surface, that is, the section of the tape does not look so smooth, showing a deviation of 0.1mm. Another kind of slit product, his tape surface looks It is very flat and has a very good appearance. These two products will not affect the use of customers when they use them.

Post time: Jul-06-2023