There are many systems that use twisted pairs in automobiles, such as electronic injection systems, audio and video entertainment systems, airbag systems, CAN networks, etc. Twisted pairs are divided into shielded twisted pairs and unshielded twisted pairs. The shielded twisted pair cable has a metal shielding layer between the twisted pair cable and the outer insulating envelope. The shielding layer can reduce radiation, prevent information leakage, and also prevent external electromagnetic interference. The use of shielded twisted pairs has a higher transmission rate than similar unshielded twisted pairs.

Shielded twisted pair wires, wire harnesses are generally used directly with finished shielded wires. For unshielded twisted pairs, manufacturers with processing capabilities generally use a twisting machine for twisting. During the processing or use of twisted wires, two important parameters that need special attention are the twisting distance and the untwisting distance.

| twist pitch

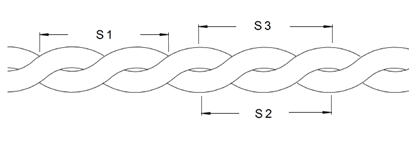

The twist length of a twisted pair refers to the distance between two adjacent wave crests or troughs on the same conductor (it can also be seen as the distance between two twisted joints in the same direction). See Figure 1. The twist length = S1 = S2 = S3.

figure 1 pitch of the stranded wireS

The lay length directly affects the signal transmission capability. Different lay lengths have different anti-interference capabilities for signals of different wavelengths. However, except for the CAN bus, relevant international and domestic standards do not clearly stipulate the twist length of twisted pairs. The GB/T 36048 Passenger Car CAN Bus Physical Layer Technical Requirements stipulates that the CAN wire lay length range is 25±5mm (33-50 twists/meter), which is consistent with the CAN lay length requirements in SAE J2284 250kbps high-speed CAN for vehicles. same.

Generally, each car company has its own twisting distance setting standards, or follows the requirements of each subsystem for the twisting distance of twisted wires. For example, Foton Motor uses a winch length of 15-20mm; some European OEMs recommend selecting the winch length according to the following standards:

1. CAN bus 20±2mm

2. Signal cable, audio cable 25±3mm

3. Drive line 40±4mm

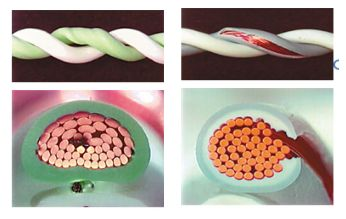

Generally speaking, the smaller the twist pitch, the better the anti-interference ability of the magnetic field, but the diameter of the wire and the bending range of the outer sheath material need to be considered, and the most appropriate twisting distance must be determined based on the transmission distance and signal wavelength. When multiple twisted pairs are laid together, it is best to use twisted pairs with different lay lengths for different signal lines to reduce interference caused by mutual inductance. The damage to the wire insulation caused by too tight a twist length can be seen in the figure below:

Figure 2 Wire deformation or cracking caused by too tight twisting distance

In addition, the twist length of twisted pairs should be kept even. The twisting pitch error of a twisted pair will directly affect its anti-interference level, and the randomness of the twisting pitch error will cause uncertainty in the prediction of twisted pair crosstalk. Twisted pair production equipment parameters The angular speed of the rotating shaft is a key factor affecting the size of the inductive coupling of the twisted pair. It must be considered during the twisted pair production process to ensure the anti-interference ability of the twisted pair.

| Untwisting distance

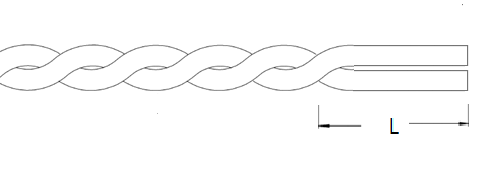

The untwisting distance refers to the size of the untwisted part of the twisted pair end conductors that need to be split when installed into the sheath. See Figure 3.

Figure 3 Untwisting distance L

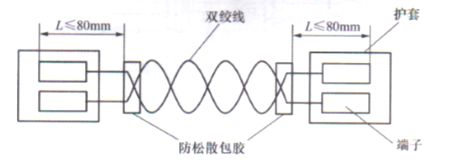

The untwisting distance is not specified in international standards. The domestic industry standard QC/T29106-2014 "Technical Conditions for Automotive Wire Harnesses" stipulates that the untwisting distance should not be greater than 80mm. See Figure 4. The American standard SAE 1939 stipulates that the twisted pair of CAN lines should not exceed 50mm in untwisted size. Therefore, the domestic industry standard regulations are not applicable to CAN lines because they are larger in size. Currently, various car companies or wiring harness manufacturers limit the untwisting distance of high-speed CAN lines to 50mm or 40mm to ensure the stability of the CAN signal. For example, Delphi's CAN bus requires an untwisting distance of less than 40mm.

Figure 4 Untwisting distance specified in QC/T 29106

In addition, during the wire harness processing process, in order to prevent the twisted wires from loosening and causing a larger untwisting distance, the untwisted areas of the twisted wires should be covered with glue. The American standard SAE 1939 stipulates that in order to maintain the twisted state of the conductors, heat shrink tubing needs to be installed at the untwisted area. Domestic industry standard QC/T 29106 stipulates the use of tape encapsulation.

| Conclusion

As a signal transmission carrier, twisted pair cables need to ensure the accuracy and stability of signal transmission, and they should have good anti-interference capabilities. The twist pitch size, twist pitch uniformity and untwisting distance of the twisted wire have an important impact on its anti-interference ability, so it needs to be paid attention to during the design and processing process.

Post time: Mar-19-2024