01 Introduction

As a power transmission carrier, high-voltage wires must be made with precision, and their conductivity must meet strong voltage and current requirements. The shielding layer is difficult to process and requires high waterproofing levels, which makes the processing of high-voltage wire harnesses difficult. When studying the process of manufacturing high-voltage wire harnesses, the first thing to consider is to solve the problems that will be encountered during processing in advance. List the problems and notes on the places that need attention in advance in the process card, such as the limit of the high-voltage connector and the location of the plug-in. The assembly sequence, heat shrink position, etc. make it clear during processing, which improves processing efficiency and also helps improve the product quality of high-voltage wire harnesses.

02 Preparation for high-voltage wire harness process production

1.1 Composition of high-voltage lines

The high-voltage wiring harness includes: high-voltage wires, high-temperature-resistant corrugated tubes, high-voltage connectors or ground iron, heat shrink tubes, and labels.

1.2 Selection of high-voltage lines

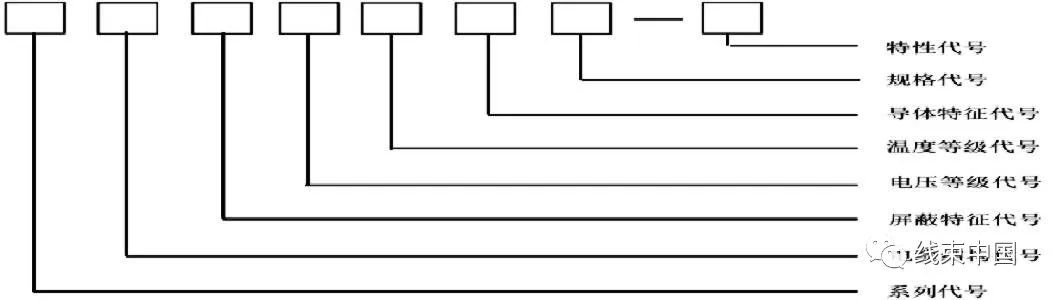

Select wires according to the drawing requirements. At present, heavy truck high-voltage wiring harnesses mostly use cables. Rated voltage: AC1000/DC1500; heat resistance level -40~125℃; flame retardant, halogen-free, low smoke characteristics; double-layer insulation with shielding layer, outer The insulation is orange. The order of models, voltage levels and specifications of high-voltage line products is shown in Figure 1:

Figure 1 Arrangement order of high-voltage line products

1.3 High voltage connector selection

High-voltage connectors that meet the selection requirements meet electrical parameters: rated voltage, rated current, contact resistance, insulation resistance, withstand voltage, ambient temperature, protection level and a series of parameters. After the connector is made into a cable assembly, the impact of the vibration of the entire vehicle and equipment on the connector or contact must be considered. The cable assembly should be routed and fixed appropriately based on the actual installation position of the wiring harness on the entire vehicle.

The specific requirements are that the cable assembly should be routed straight out from the end of the connector, and the first fixed point should be set within 130mm to ensure that there is no relative displacement between the fixed point and the device-side connector such as shaking or movement. After the first fixed point , no more than 300mm, and fixed at intervals, and the cable bends must be fixed separately. Moreover, when assembling the cable assembly, do not pull the wire harness too tight to avoid pulling between the fixed points of the wire harness when the vehicle is in a bumpy state, thereby stretching the wire harness, causing virtual connections at the internal contacts of the wire harness or even breaking the wires.

1.4 Selection of auxiliary materials

The bellows is closed and the color is orange. The inner diameter of the bellows meets the specifications of the cable. The gap after assembly is less than 3mm. The material of the bellows is nylon PA6. The temperature resistance range is -40~125℃. It is flame retardant and salt spray resistant. corrosion. The heat lock tube is made of glue-containing heat shrinkable tube, which meets the specifications of the wire; the labels are red for the positive pole, black for the negative pole, and yellow for the product number, with clear writing.

03 High wire harness process production

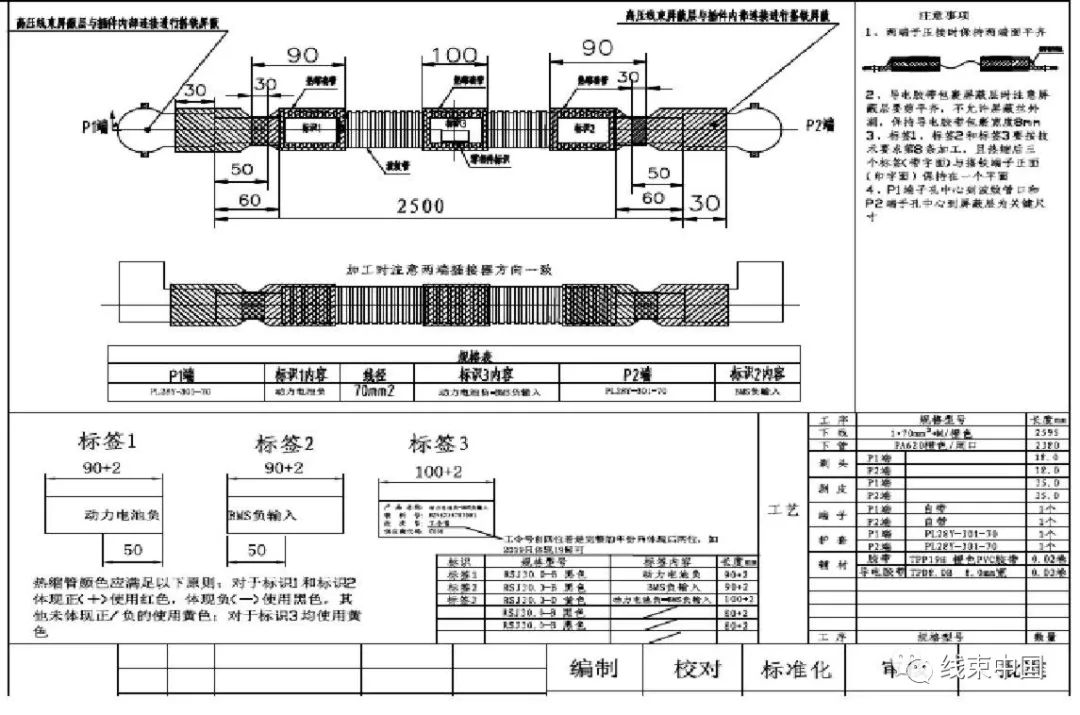

Preliminary selection is the most important preparation for high-voltage wiring harnesses, which requires a lot of effort to analyze materials, drawing requirements, and material specifications. The production of high-voltage wire harness technology requires complete and clear information to ensure that the key points, difficulties, and matters that need attention can be clearly judged during the processing process. During the processing, it is made completely according to the requirements of the process card, as shown in Figure 2:

Figure 2 Process card

(1) The left side of the process card shows the technical requirements, and all references are subject to the technical requirements; the right side shows the precautions: keep the end faces flush when the terminals are crimped, keep the labels on the same plane when heat shrinking, and the key to the shielding layer Size, hole position restrictions of special connectors, etc.

(2) Select the specifications of the required materials in advance. Wire diameter and length: High-voltage wires range from 25mm2 to 125mm2. They are selected according to their functions. For example, controllers and BMS need to choose large square wires. For batteries, small square wires need to be selected. The length needs to be adjusted according to the margin of the plug-in. Stripping and stripping of wires: Crimping of wires requires stripping off a certain length of copper wire crimping terminals. Select the appropriate stripping head according to the terminal type. For example, SC70-8 needs to be stripped of 18mm; the length and size of the lower tube: The diameter of the pipe is selected according to the specifications of the wire. The size of the heat shrink tube: The heat shrink tube is selected according to the specifications of the wire. Print label and location: identify the unified font and required auxiliary materials.

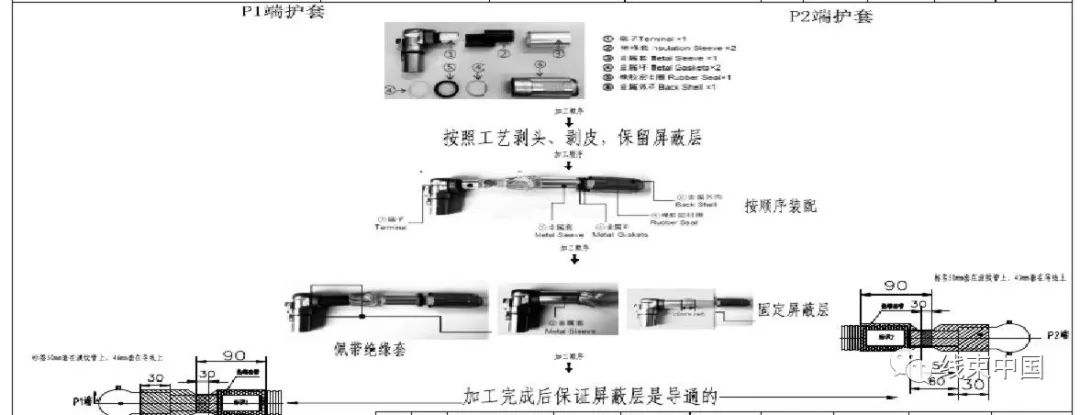

(3) The assembly sequence of special connectors (as shown in Figure 3): generally includes dust cover, plug housing parts, jack parts, elbow accessories, shielding rings, sealing parts, compression nuts, etc.; according to Sequential assembly and crimping. How to deal with the shielding layer: Generally, there will be a shielding ring inside the connector. After wrapping it with conductive tape, it is connected to the shielding ring and connected to the shell, or the lead wire is connected to the ground.

Figure 3 Special connector assembly sequence

After all the above is determined, the information on the process card is basically complete. According to the template of the new energy process card, a standard process card can be generated and produced according to the requirements of the process, fully realizing the efficient and batch production of high-voltage lines.

Post time: Mar-14-2024